Plastic Powder Coated Steel Wire

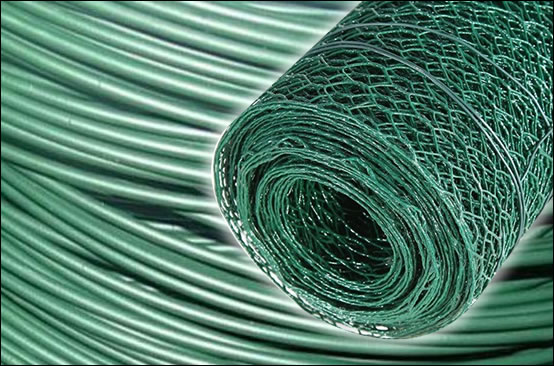

Galvanized and plastic coated wire is used in manufacturing of binding wire, tie wire, plant support wire, meshes and fences.

PVC / plastic coated steel wire is processed with coating a layer of polyvinyl chloride or polyethylene on the surface of the core wires ( annealed wire, galvanized wire, stainless steel wire, Galfan wires, etc). The coating layer firmly bonded to the wire render the features of anti-aging, anti-corrosion, anti-cracking, long life and other characteristics.

Color Coating Materials: PVC / PE / Vinyl

PVC is the most popular powder for coating wires, as it is relatively low in cost, resilient, fire retardant and possesses good insulating properties. The PVC coating and the inside wire are firmly bonded together to offer a longer service life. High-density hard PVC (vinyl chloride) coating is applied against the corrosion of common acids and alkalis. The service life is up to 12 years, that is several times that of hot and cold galvanized iron wire. The colors can be customized according to customers needs.

The coating materials of PVC, PE, polyvinyl chloride, can be added with anti-UV, anti-aging additives to achieve enhanced properties.

Differences of PVC coating and PVC dipping

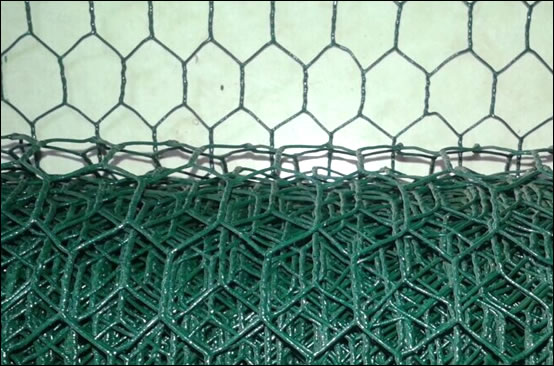

Plastic coating is a technical processing referring to the surface processing of the metal wire. The solid plastic is melt into liquid plastic under high temperature, then the metal wire material is put into plastic flow, it is taken out after certain time. Plastic Dipping is a process referring to the surface treatment on the finished steel wire mesh. Welded or woven wire mesh is treated with PVC dipping to achieve further protection from the weather and better anti-corrosion property.

In general, plastic coating mainly applies to the wire before further weaving or fabricating. The plastic dipping normally applies to the wire mesh processed with the steel wire.

Coated Wire Applications

1. Tie Wire / Binding Wire:

PVC / PE / Vinyl coated or painted wire is made in forms easy for binding and tying uses. The wire is popularly made into cut wire, cut and looped wire, or wound in coils, around sticks.

2. Hanger Wire

3. Mesh and Fencing Wire: For making of chain link fence, gabions and various meshes.

4. Vegetable and plant suppot wire

Main Parameters of Plastic Coated Wire

1, Material before coating:

Steel wire;

galvanized wire;

redrawing wire;

annealed wire;

stainless steel wire.

The wire gauge number, tensile strength, elongation, the amount of zinc and other parameters shall be pre-determined before the plastic coating processing. Average tensile strength for the PVC coated wire ranges from 350N/MM2-900N/MM2, elongation ranges from 8% -15%.

2, Coating Color:

Common colors are grass green (light green), dark green (dark green),Gray, White.

3, General Wire diameter with and without plastic coating:

Wire diameter before coating: 0.6mm-4.0mm (wire gauge BWG23-8)

Wire diameter with coating: 0.9mm-5.0mm (BWG20-7)

Plastic layer (0.4mm-1.5mm), wire diameter deviation (+0.05 mm/-0.05mm Max)

Main Products Delivered

20 SWG PVC Coated Binding Wire

PVC Coated M.S. binding wire

Gauge:

20 SWG

Galvanized PVC Coated Wire

Green

Wire size: 14 gauge or 1.628 MM

Material: Mild drawn or rolled

Inside: 1.60mm electro galvanized wire, outer diameter:2.60mm

Tensile strength: Min. 380MPa.

Elongation: Min. 9%

Green PVC Wire to Poland

Pvc wire, green rd 2,40/2,75 mm

Pvc wire green, rd 2,75/3,15 mm

Pvc wire green, rd 1,80/2,20 mm

Rm: 450/550 NM

Colour: ral 6009 (or similar)

In coils: 400/800kg.

Supply in FCL

PVC Coated Electro Galvanised Wire 2.00mm

Specs: 1.6mm/2.0mm

Tensile Strength: 35-50kgs/mm2

Colour: Dark Green RAL6005

Roll Weight: 500kgs/roll

Packing: Inner Plastic Film and Outer Woven Bag

PVC Coated Electro Galvanised Wire 2.80mm

Specs: 2.0mm/2.8mm

Tensile Strength: 35-50kgs/mm2

Colour: Dark Green RAL6005

Roll Weight: 500kgs/roll

Packing: Inner Plastic Film and Outer Woven Bag

Galvanised wire with PVC coated, Delivered to Portuguese

Hot-dipped galvanized wire with PVC coating

Wire Diameter:

Inner 1.9mm, outside diameter 3mm

Inner 2.6mm, outside diameter 4mm

Material: Low carbon to DIN 1548

Tensile Strength (T/S) 40-44kgs/mm2 max 45kgs/mm2

Diam. tolerance to DIN 177

Zinc coating 70-80gms

PVC color RAL 6005 (dark green)

Packing: should be in coils of about 600Kgs

Annealed Wire, Plastic Coated

Pvc coated wire coils, green, inner soft annealed wire, wire diameter 3 mm after coating, delivered to Mexico market

Green PVC Coated Wire for Gabions Production

3.20 PVC Coated Wire:

Inner Wire: 2.20mm

Finish:

Zn90%, Al%10 Coated ( min 230 gr/m2) +Further PVC Coated

Tensile Strength: 350 - 500 N/mm2

3.70 PVC Coated Wire

Inner Wire: 2.70mm

Finish:

Zn90%,Al%10 Coated ( min 245 gr/m2) +Further PVC Coating

Tensile Strength: 350 - 500 N/mm2

3.70 PVC Coated Wire

Inner Wire: 2.70mm Zn95%, Al%5 Coated ( min 245 gr/m2) + Further PVC Coating

Tensile Strength: 350 - 500 N/mm2

PVC Coated Wire for Packing Purpose

pvc coated binding wire

Core wire diameter: 0.8 MM

Coated wire diameter: 1.2 MM

Core wire material: Galvanised wire

For packing of big bulks

Powder coated GI wire for packing, size 1.2mm

PVC Coated Galvanized Wire in Big Coils

Diameter 3.76/4.16mm

Tensile strength 45 to 50 kg/m2

Base wire zinc coating: 70g/m2

PVC Color - RAL 6005

Specifications BS EN10244 Class C.

Packing in 500KG coil

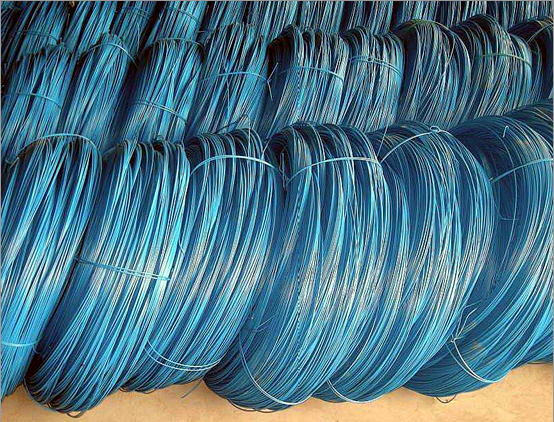

Colour Coated Steel Wire, in Black and other Colors

19 gauge tie wire, with black PE coating, white, blue and other colors available

Blue Coated PVC Wire Delivered to India

Coated galvanized iron wire, 3.5 mm, delivered to India, blue powder coated

Cut Binding Wire

PVC coated galvanized iron tie wire, cut in pieces of 48” , for tying / binding

PVC Coated Barbed Wire for Fencing Uses

2 strands and 4 points twisted. Barbs' distance can be 3-6 inches with a tolerance at 1/2" less or more.

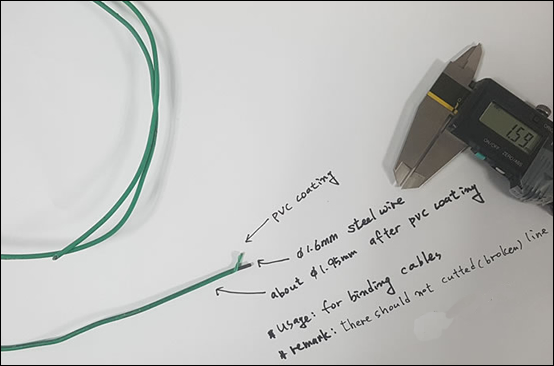

PVC Coated Soft Steel Binding Wire Delivered to Korea

Inner steel wire dia 1.6mm

PVC coated wire dia 2.0mm

Pvc coating with green color

Usage: for binding cables

Bobbin: 2,500 meter

6mm x 1.5m Plant Support Wire Trellis

Made out of galvanize steel wire or plastic coated steel wire. Used to prevent the tomato plants from sprawling all over the vegetable garden, easy to use and cost less compared with tomato cages.

PVC coated wire for wire mesh project

Mesh wire Inner diaL: 2.70 mm

Mesh Wire Outer dia : 3.70 mm

Colour: Grey / Dark Green

Coil Weight: 50 kgs

Green Florist Wire

Surface: Plastified (Plastic Coated), mostly in green color

Wire length 25m

Tensile 37-43kgs/mm2

Elogation 16.6-17.5%

PVC Coated Steel Wire for Greenhouses and Tunnels

PVC coated wire of size 2.5 / 3.5mm

PVC Coated Wire, 16 gauge Delivered to UA

Size:0 .062" diameter steel wire

Coated with PVC or equivalent in black color.

Material: C1008 Carbon

In Coils of 100lbs.

Sample available upon request

PVC Coated Steel Wire for Making PVC Clothes Hangers

PVC Coated Wire (2.6 - 2.7 - 2.8 mm)

Export to Saudi Arabia

For making wire clothing hangers

Wire hangers sizes (2.6 - 2.7 - 2.8 mm)

Processing

1, Wire Drawing

Metal wires can be drawn in two ways: Powder drawing and water drawing.

Powder drawing is applied for primary or junior drawing (6.5mm~4.0mm). Usually the powder drawing machine has 4 tanks and 4 molds. One tank is matched with a mold. Each of them are offered energy by a electromotor. 0.9mm (max) can be reduced when the wire cross a mold. There are no loss of weight during drawing. In this kind of drawing process, powder is used as lubricant, which is made of soap and butter. Mold is hidden behind the powder.

Water drawing is used for senior draw or fine drawing (≤4.0mm). The container is filled with water, soap and 8 molds. Compared with powder draw, water drawing needs less space. Also the wire is thinner fter drawing, and stronger. The tensile strength is about 700N. The wire thus drawn can be used for nail and mesh panel production.

2. Annealing

Annealing is required for galvanized wire.

This process is to low the tensile strength of wire. The stove is solid and built with red bricks. The architecture of anneal stove is cuboid. Different thickness of wire require different temperature. Range is from 700°C to 900°C. Output of the anneal stove, the tensile strength is 400N~600N.

3. Chlorhydric acid washing

Galvanized wire's third stage is chlorhydric acid washing.

After the draw and anneal, the wire is thinner, softer but also much more dirty. It needs chlorhydric acid washing to remove the impurities. Chlorhydric acid washing requires water pool and chlorhydric acid pool. The density of chlorhydric acid is 17%. In the Chlorhydric acid pool, there is a caldron used for the emission of vapor.

4. Electro zinc coating

Galvanized wire's fourth stage: Zinc coating

After the chlorhydric acid pool, water pool is also necessary. In the zinc pool, displacement reaction is chemical and uniformly distributed. The surface of wire is smooth. Because wire cross the zinc pool fast, abundant zinc coating requires 4 zinc pools.

5. Powder Coating

Powder coating is to bond the powder onto the surface of the metal wire through a device (electrostatic spray machine). The powder will be uniformly adsorbed on the surface of the metal wire to form a powder coating. The spraying effect is superior to the painting process in terms of mechanical strength, adhesion, corrosion resistance, and aging resistance, and the cost is much lower.